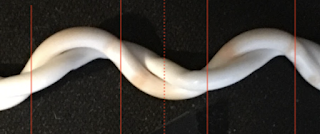

Opening all the seams should leave the work connected and planar: if we find the work is disconnected, unnecessary seams were made; if we find the work is still nonplanar, some unopened seams must remain in the work.

Opened up in this way, the work is a polygon with an even number of edges, two for each seam. This is referred to as a polygonal model or planar model in topology texts.

A planar model corresponds to a single-face map drawn on the surface. Each seam is represented by an edge in the map and two paired edges in the polygonal model. Each edge in the map necessarily borders the single face on both sides, and thus is encountered twice in a walk around the perimeter of the face. In an orientable surface the second passage along the same edge must be in the opposite direction of the first. In algebraic topology the sequence of edges encountered is described by an edge word, such as aba-1b-1, where the inverse indicates traversing the edge in the opposite direction.

For the orientable surfaces that concern us, as the paired edges will always join in the natural, untwisted orientation. Therefore, we can indicate the pairings by simply adding to the polygon diagram some curvy lines connecting edge pairs, as in the figure above.

Many ways of seaming are possible, but only some can encoded in undip efficiently by the addition of a specialized u and d. These are namely the seam designs that can be diagrammed on the planar model without crossing lines (for example, Canonical and Longitude/Latitude in the figure above.) The specialized u and d are only needed for bonds that violate planarity by trespassing on the regular weaving in the interior of the polygonal model.

Canonical starts and finishes one handle at a time. Opposite Sides has all the handles in progress at one time but results in a maximally non-planar diagram. Longitude/Latitude uses nearly twice as many edges as the other designs, has all handles in progress at one time, but is planar, so it can be encoded in undip with just the specialized u and d.

Many ways of seaming are possible, but only some can encoded in undip efficiently by the addition of a specialized u and d. These are namely the seam designs that can be diagrammed on the planar model without crossing lines (for example, Canonical and Longitude/Latitude in the figure above.) The specialized u and d are only needed for bonds that violate planarity by trespassing on the regular weaving in the interior of the polygonal model.

Canonical starts and finishes one handle at a time. Opposite Sides has all the handles in progress at one time but results in a maximally non-planar diagram. Longitude/Latitude uses nearly twice as many edges as the other designs, has all handles in progress at one time, but is planar, so it can be encoded in undip with just the specialized u and d.