Just as pixelated curves in computer graphics are never actually smooth, equilateral surfaces are always crinkly. They have a quantized surface curvature that results in a crinkly surface texture no matter how closely they might approximate a smooth surface in their gross trajectory. A nearly smooth triangulation always has non-equilateral triangles.

The diagram below shows a non-equilateral triangulation of the plane that is representative of what happens when a slightly curved surface is triangulated with triangles as nearly equilateral as possible. Topological irregularities inevitably occur, such as 5 or 7 triangles around a vertex (a topological charge of +1 or -1) in a sea of 6-triangle vertices (topological charge = 0), yet the surface remains nearly flat. This results in some noticeably non-equilateral triangles, especially near charged vertices.

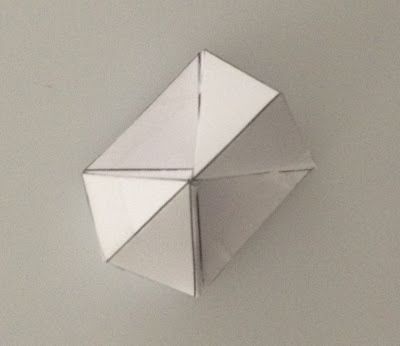

Often a 5-triangle vertex will neighbor a 7-triangle vertex—a topological dipole so to speak. Two of the triangle strips in the triangulation will pass directly through such a dipole, and both will show a distinct curvature, bending toward the +1 vertex (5 triangles) and away from the -1 vertex (7 triangles.) In the diagram below the constructions follow the path of a triangle strip that passes through a dipole.

Any way we wish to corrugate such a strip, the tendency will be for the weaver, when laid out flat, to curve in the same direction as the corrugated strip viewed in projection. Whether we wish to get involved with custom bending, or custom cutting and bending, any curvature in the before-folding, laid-out-flat conformation is an expensive problem.

A few degrees of freedom are available in attempting to avoid this before-folding curvature. The nominally 6-way crossings can be left somewhat open (as they are in conventional kagome) and the 3-way crossings can be adjusted in 3-dimensional space somewhere above their corresponding triangles.

A starting point is to place each 3-way crossing directly above the center of the triangles inscribed circle. In this arrangement the distance (as measured on each weaver) between a 3-way crossing and the valley fold below it can be made the same everywhere. Laying the weaver out flat causes the local waviness to nearly disappear, but the overall curvature remains.

|

| Path of corrugated weaver through a non-equilateral triangulation. |

|

| A corrugated weaver with its 3-way crossings overlying with the incenters (centers inscribed circles) of the triangulation. |

|

| Laying the corrugated weaver out nearly flat causes the waviness of the weaver's projected path to nearly disappear, but the gross curvature of the path remains. |